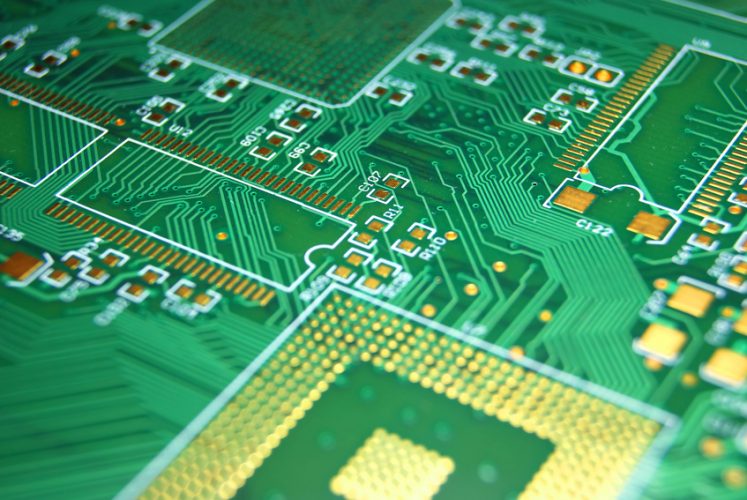

When building prototype circuit boards, engineers typically focus the majority of their attention on formatting the circuits to ensure the prototype PCB is functional at the end of fabrication. So this leaves the PCB layout itself to be neglected, which can cause reliability problems.

Here are some PCB layout tips and tricks every designer needs to know to prevent this from happening.

Sizing Traces

A copper track is a conductive path used to connect two points within the PCB, and the ones that are used in PCB assembly have resistance. Typically, PCB designers use length, width, and thickness to control the resistance of the trace, and it is measured in ounces of copper. Many designers use anywhere between one and six ounces of copper to provide different levels of thickness. To determine the optimal thickness for your specific project, use a PCB trace width calculator and aim for a 41 degree Fahrenheit rise.

Also, it is important to remember that traces on the external layers will cool off better when the heat from the internal layers must travel through layers of copper before being conducted. In respect to this, the most simple printed circuit boards are the ones that contain copper tracks or interconnects on only one of their surfaces. These are known as 1 layer PCBs.

Make The Loops Small

Loops, especially the larger ones, should be made as small as possible, because smaller loops have lower inductance and resistance. Plus, a PCB with high loops reduces the amount of high frequency voltage spikes.

Decoupling Capacitor Placement

Place these capacitors as near as possible to the power and ground pins of integrated circuits to increase efficiency. If you place the capacitors farther away, it will reduce their inductance ability.

Keep Noise Traces Away From Analog Traces

Placing these two types of traces together doubles the signals on the traces, which can lead to interference and short-circuiting. A good rule of thumb is to keep these high frequency traces away from those you do not want noise on.

Leave Room

It is important that you leave room between copper traces and fills to prevent shock hazards. Solder mark isn’t always a reliable conductor, so make sure there is a good amount of distance between the two.

Follow these tips to have a reliable and efficient PCB layout! And if you still need help with your designs, contact PCB Unlimited’s experts for more information.

There is certainly a great deal to know about this issue. I

like all the points you made.

I could not refrain from commenting. Perfectly written!