Improve Efficiency

Combining multiple wires into one assembly, reduces clutter and improve organization.

PCB Unlimited provides wire harness manufacturing services tailored to a broad range of industries, including aerospace, automotive, industrial equipment, medical devices, and telecommunications.

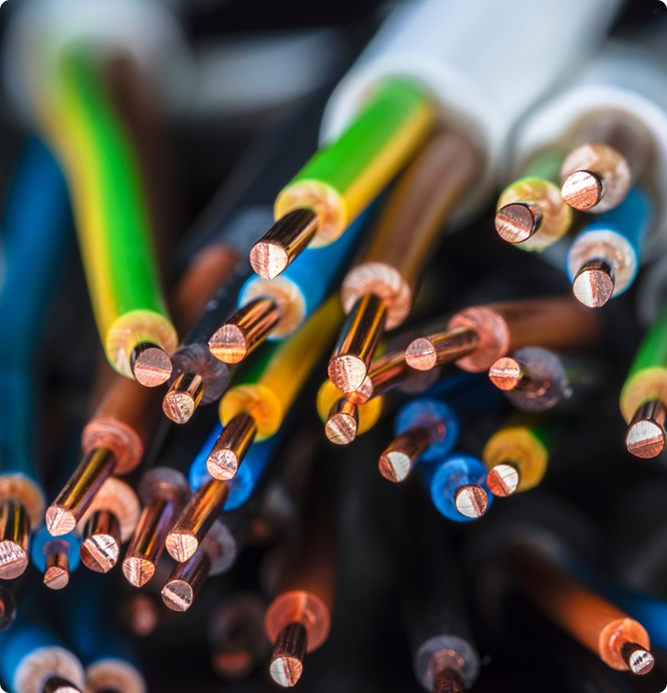

A wire harness is a collection of wires, cables, connectors and other components (please refer to Components of a Wire Harness) bundled together in a specific way to transmit electrical power or signals within a device, machine, or system.

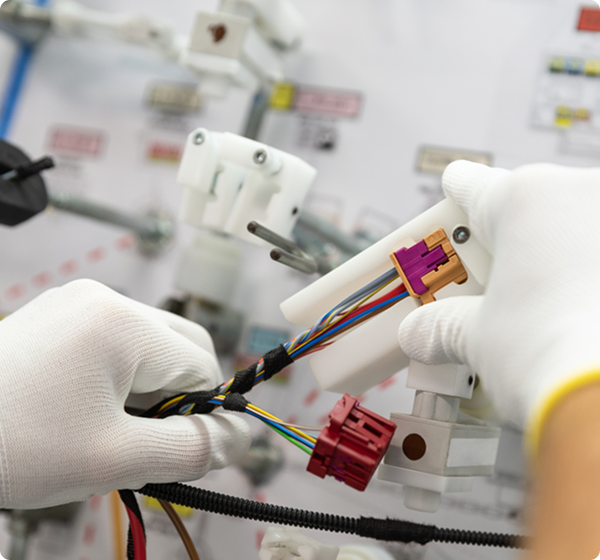

Wire harness manufacturing is the complete process of designing, assembling, and testing. It typically involves cutting, stripping, terminating, and assembling wires using a combination of automated machinery and manual labor, due to the complexity and variation of tasks involved.

Combining multiple wires into one assembly, reduces clutter and improve organization.

Wire harnesses reduce material waste and installation time. They also lower production cost by simplifying manufacturing and assembly.

They minimize the risk of electrical hazards like shorts and fires.

Protective sleeving and insulation enable harnesses to withstand mechanical stress and environmental exposure, extending the lifespan of the electrical system.

Combining multiple wires into one assembly, reduces clutter and improves overall system design.

They reduce the complexity of the installation process.

The Schleuniger EcoCut 3300 can automatically cut all kinds of material including wire, cable, round material such as tubing, flat ribbon and Glass Fiber Optic (GOF) cable.

It processes wire up to 16 mm² (6 AWG), cuts round material up to 12 mm (0.47") O.D. and cuts flat material up to 100 mm (3.94") wide.

Flat Cables

Flat Cables

Round cables, profile

Round cables, profile

Shrink Tubing

Shrink Tubing

Thin metallic, nonmetallic sheets

Thin metallic, nonmetallic sheets

Tubing

Tubing

Wire marking

Wire marking

Woven fabric

Woven fabric

The Schleuniger Strip Series B300 stripping machine performs reliable stripping of cables with cross sections from 0.03 to 8 mm2 (32 to 8 AWG).

Discrete Wire Processing

Discrete Wire Processing

Full Strip

Full Strip

Partial Strip

Partial Strip

The Schleuniger MultiStrip 9480 is a high-performance, fully automatic wire cutting and stripping machine designed for precision and versatility for a variety of wire harness applications.

Cut to length

Cut to length

Full or partial strip left and right

Full or partial strip left and right

Jacket and inner conductor stripping

Jacket and inner conductor stripping

Jacket stripping of extremely thin insulations

Jacket stripping of extremely thin insulations

Multilayer stripping

Multilayer stripping

Multilayer with shield processing (coax, hybrid, etc.)

Multilayer with shield processing (coax, hybrid, etc.)

Multistep jacket stripping with inner conductor stripping and window slitting

Multistep jacket stripping with inner conductor stripping and window slitting

Multistep stripping

Multistep stripping

Trimming, separating and stripping of individual zipcord conductors

Trimming, separating and stripping of individual zipcord conductors

Wire marking

Wire marking

The Schleuniger CT 60 is a pneumatic benchtop crimping machine engineered for high-force, loose-piece crimping applications. It delivers up to 60 kN (6.7 tons) of parallel crimping force, making it suitable for processing a wide range of terminal types and wire sizes.

The quality of the crimp is guaranteed by a full-cycle mechanism that assures that the dies have closed completely before they are reopened.

The Schleuniger UniCrimp 208 is a high-performance benchtop crimping machine designed for precise and efficient crimping of rear-feed and side-feed banded terminals. With a crimping force of 33 kN (3.3 tons), it accommodates a wide range of wire sizes and terminal types, making it ideal for various wire harness assembly applications.

Discrete wire crimping

Discrete wire crimping

The Schleuniger StripCrimp 208 stripping machine combines the standard working processes of cable processing in a single machine. Short breakout lengths of 22 mm (0.86") and even down to 10 mm (0.39") using special tools permit the processing of sensor applications.

Discrete wire crimping

Discrete wire crimping

Discrete wire stripping

Discrete wire stripping

Discrete wire stripping & crimping

Discrete wire stripping & crimping

Multistep stripping

Multistep stripping

The semiautomatic Schleuniger CoaxStrip 6480 stripping machine processes coaxial cables with an outer diameter of 1.2 to 12 millimeters.

It is equipped with "cable end detection" and "cable diameter verification."

The WTT Wire Terminal Pull Tester is designed to test the pull-out force of crimped wire terminals. It features a digital display for accurate force measurement and can be used for quality control in wire harness production.

The tester helps ensure that crimped connections meet required specifications and industry standards for pull-out strength.

Conductors —typically copper or aluminum— that transmit electrical power or signals.

Interface devices that securely connect wires to other wires or components.

Points in the harness where wires connect to other components using metal end crimping or soldering.

A layer of material used to protect the wires and prevent shorts, moisture, and environmental damage.

Additional coverings such as plastic tubing, fabric wrap, or heat shrink to shield wires from abrasion, heat, and moisture.

Clips, ties, or fasteners used to secure the wire harness in place.

Wires are cut to precise lengths using wire cutters for prototyping or small batch or automated machines like the MultiStrip 9480.

Wires are stripped by removing the insulation at connection points without damaging the conductor.

Wires are labeled with inkjet printers or heat shrink markers.

Terminals are attached to wires using manual tools or crimping machines like CT 60. Some applications require soldering for extra strength or conductivity.

Wires are routed on a layout board using clamps and connectors.

Wires are inserted into connectors and protective sleeves. Heat-shrink tubing can be used for sealing.

Electrical testing includes continuity, shorts and pinout verification.

Harnesses are labeled with part numbers, revision numbers, and other identifiers.

They are packaged safely to prevent damage during shipping.

Designed to handle heat, vibration, and chemical exposure in engines, lighting systems, and safety systems.

High-reliability harnesses support critical avionics and communication systems.

Biocompatible and miniaturized harnesses are used in imaging equipment, diagnostic tools, and patient monitors.

Designed for rugged environments to power automated systems and robotics.

Compact harnesses are used to streamline connections and reduce clutter in appliances, computers, and audio systems.

If you're looking for more technical details or advice on wire harness design, manufacturing, or suppliers, feel free to ask!