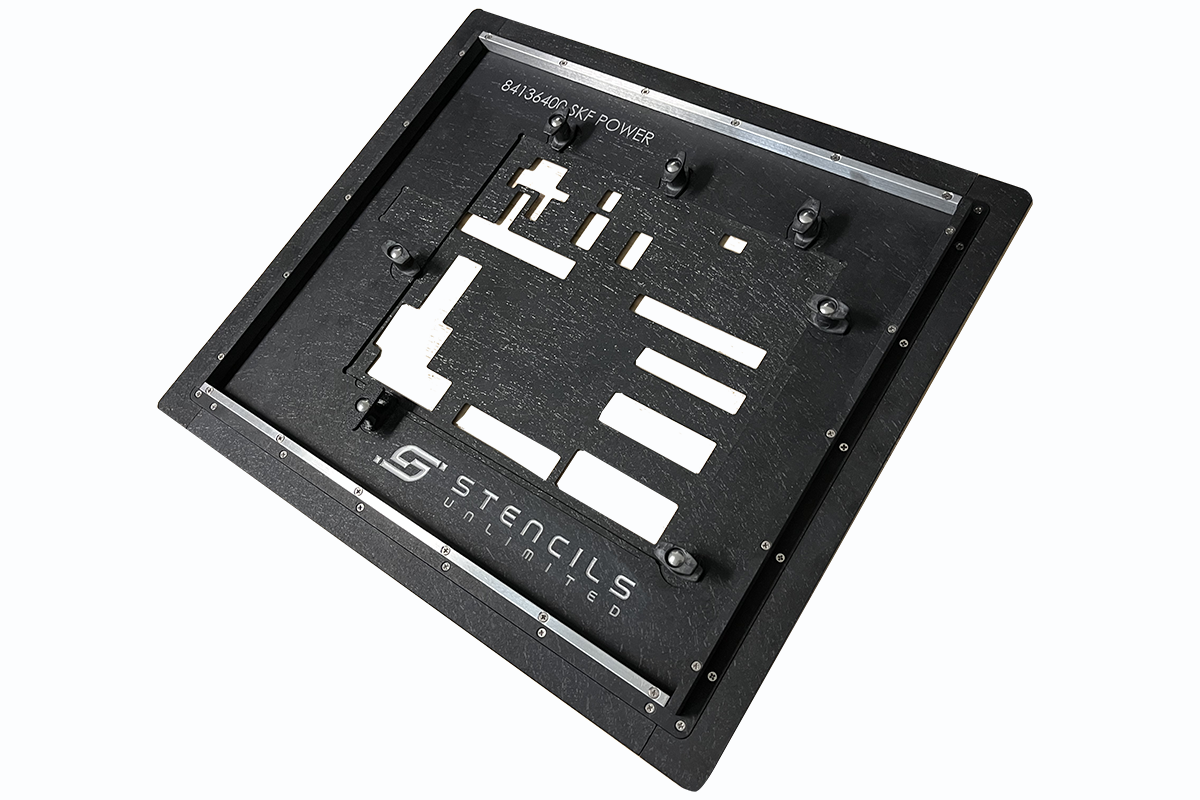

During the manufacturing process, material is removed from the pallet in areas where the printed circuit board needs to be exposed to solder. Material is left on the pallet in areas where the PCB needs to be covered in particular areas containing surface mount components, mounting holes, gold fingers and ground planes.

PCB Unlimited offers production and prototype wave solder pallets. Our production wave solder pallets are made with an ESD composite, pressed fibre, thermoset plastic which can be machined to create wave pallets and SMT fixtures. Our prototype wave solder pallets are made with high Tg FR4 (PCB material) to reduce manufacturing cost and lead time in addition to the following characteristics:

You can request a custom quote or quote and order your pallets online. Please follow the next steps to quote and order online.

Our technicians use the latest technology in CNC machining to fabricate wave solder pallets. Fabrication mainly consists of removing material from areas of the pallet where the circuit board is to be exposed to the wave, and solder is required.

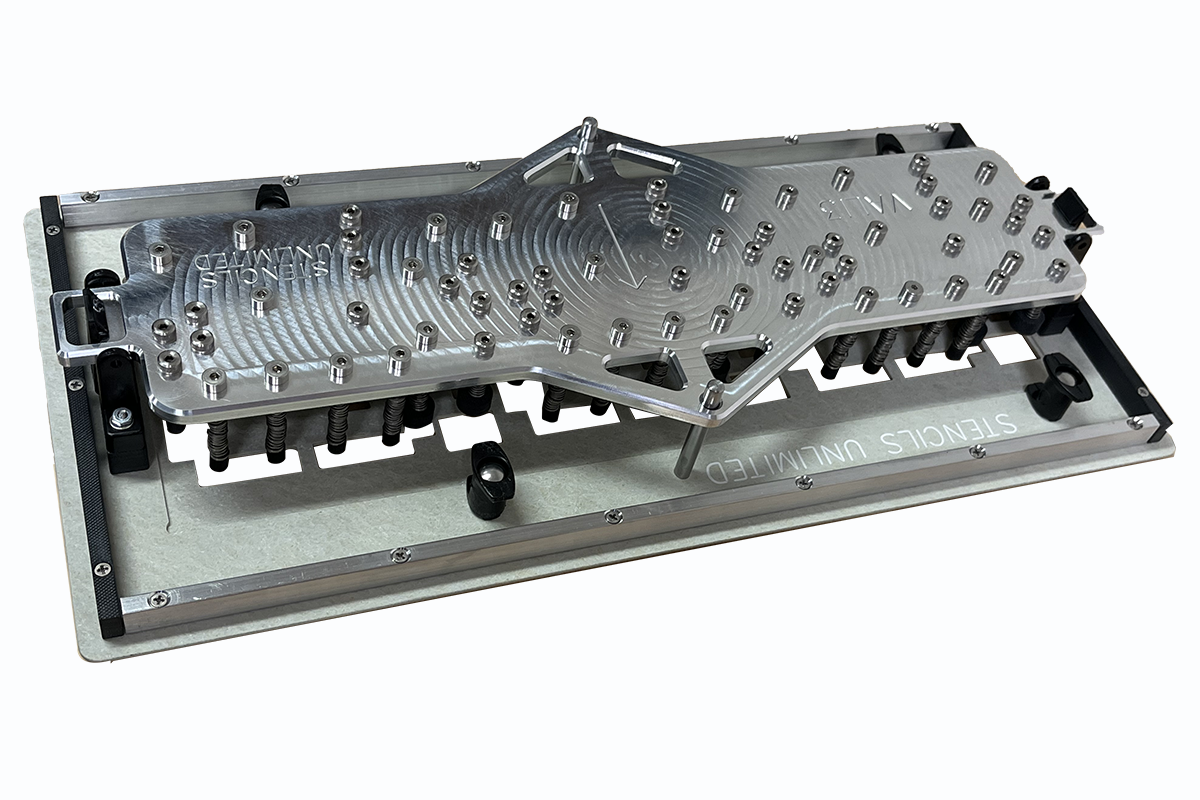

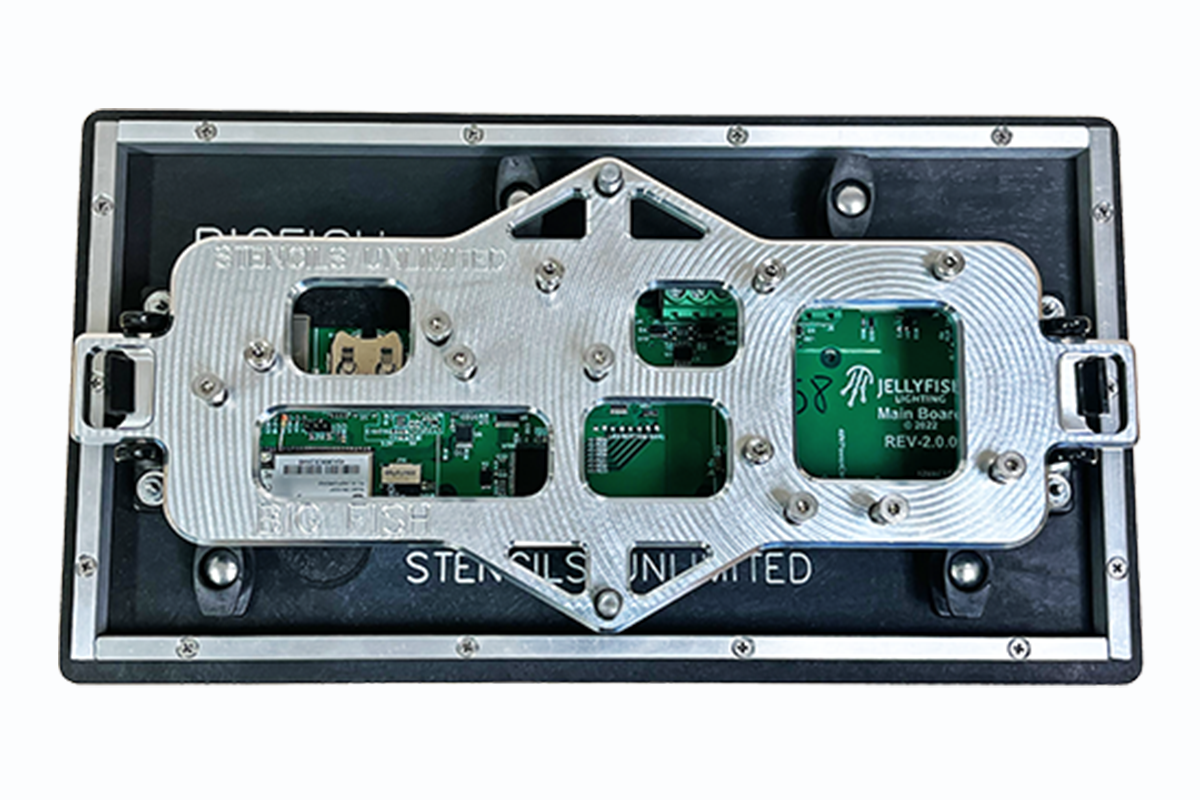

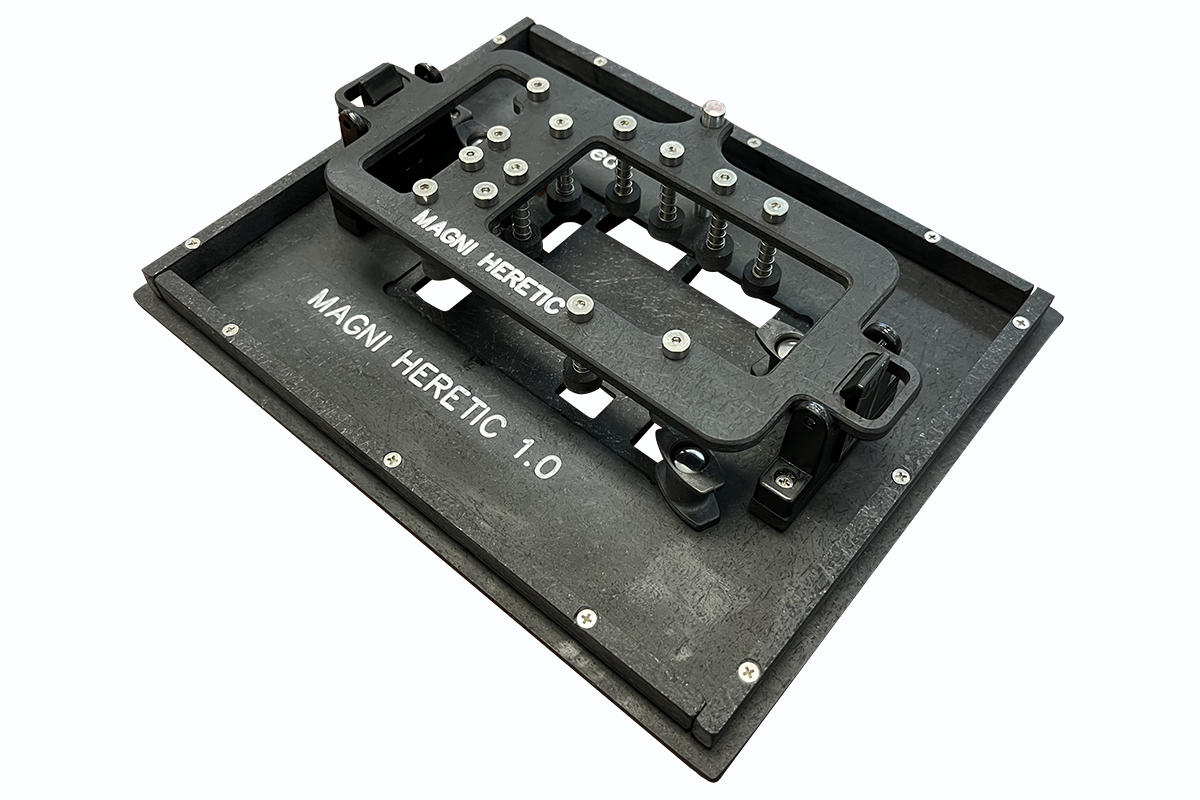

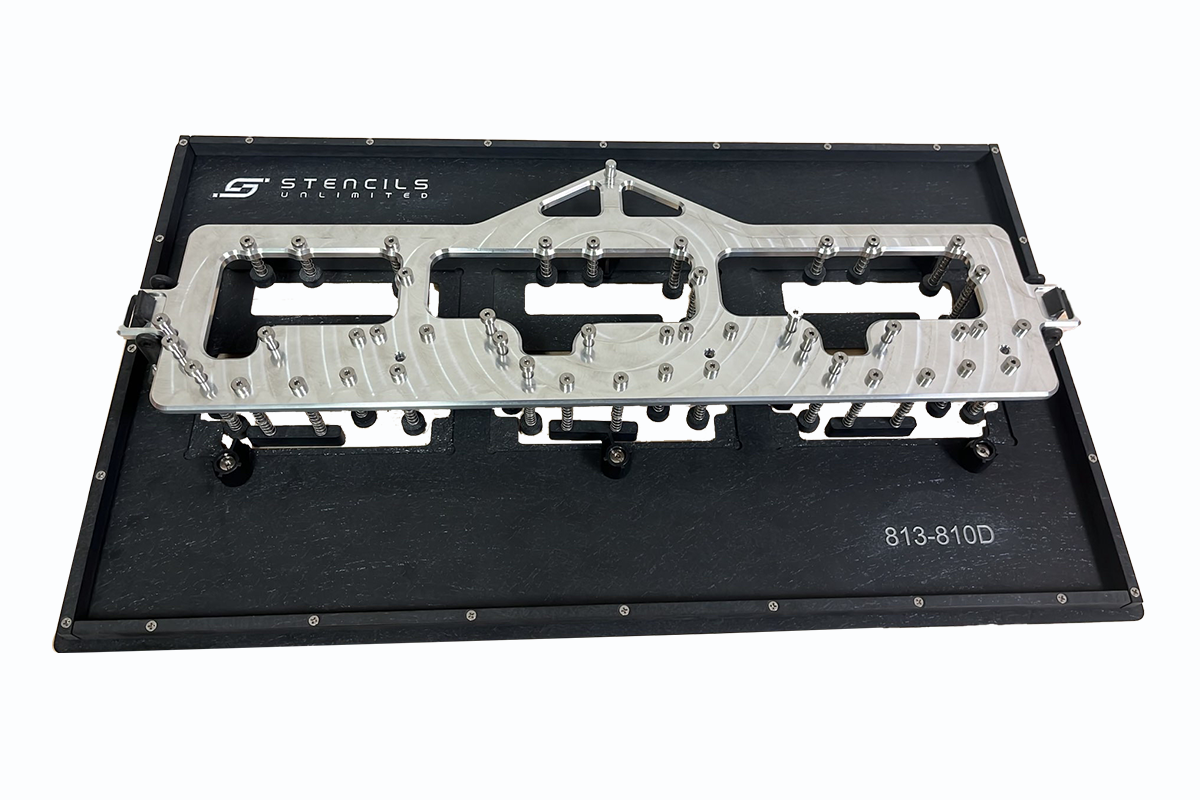

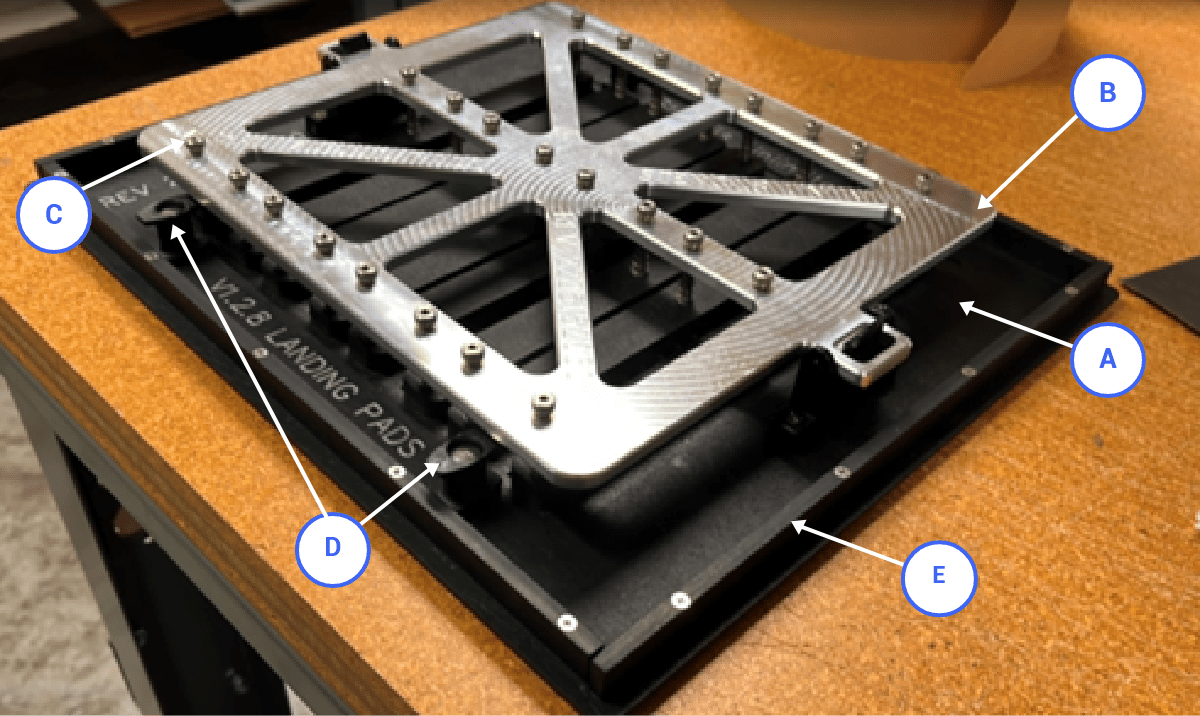

Every wave solder pallet is custom designed to fit a specific PCB layout and meet unique process requirements however, they usually have the following components:

A) Base plate: Also known as base pallet serves as the foundation for the pallet and provides a flat surface for the PCB to rest on during soldering. It typically features cutouts and openings that allow the solder to flow through and create the necessary solder joints, while protecting the components from being damaged.

B) Top hat: Also known as Cover Plate, is designed to hold the components in place during wave soldering and sits on top of the Base Plate. It typically features openings to reduce weight.

C) Alignment dowels: They are used to ensure the Top Hat is correctly positioned above the PCBs.

D) Hold downs: They hold the PCB securely in place. They are commonly made of titanium and plastic instead of steel to avoid cross contamination.

E) Stiffener Bars - They are used to provide support to the pallet to reduce twisting and bending. They also prevent solder from going over the top area of the pallet.

F) Gas relief: Also known as vent holes are indentations on the pallet to allow gases to escape during soldering. They also help to prevent defects such as solder voids or insufficient wetting, which can occur when gases become trapped in the solder joint.