If you are designing a prototype circuit board, then there are a few general rules to follow in order to make the entire PCB fabrication process go by smoothly. Here we have compiled some tips and tricks that will help any beginner assemble their first circuit board like a pro.

Placing components

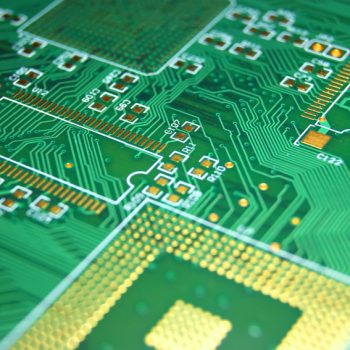

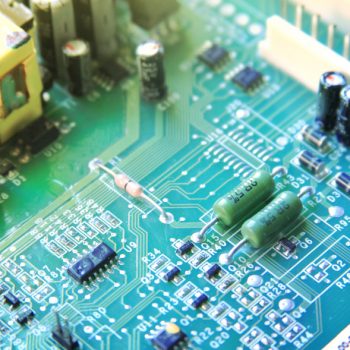

There are three major types of prototype PCBs, single-sided, double-sided, and multi-layered. Each type of board has different rules for each of their components, but as a rule of thumb it is always a good idea to place parts on the top side of the board. It is important to place all components in their specific locations, including switch connectors, LED, mounting holes, or heat sinks.

The goal is to minimize trace lengths between components to make sure the prototype printed circuit boards do not short circuit. Simply put parts that connect to each other next to one another, and it will be easier to lay the traces down the road.

ICs should only be placed on the board in one position, either up and down or left to right. Doing more than this can cause confusion in the board’s circuitry. You will also save a lot of time if you leave plenty of room between these components, as the tracing lines must go between them.

When you are done properly placing all of the components, print a copy of the layout and place it over the prototype circuit board. This way you can check to make sure there is enough space for each component without them touching each other, and then you can complete the soldering process.

Placing ground and power traces

After soldering the components the next step is to lay the power and ground traces. The power and ground lines are essential when working with the IC as they will connect to common rails for each supply. This is a way to avoid daisy-chaining power lines from part-to-part.

Placing signal traces

The goal here is to make the signal traces as short and as direct as possible. Feed through holes, called vias, are able to move signals from one layer to the other, so use these to your advantage. Also, traces that carry a larger current should be wider than any other signal traces to prevent short-circuiting.

PCB fabrication is meant to be fun. So follow these tips to discover the world of printed circuit boards for the first time!

Quality Circuit Assembly provides high quality services for PCB Assembly, Turnkey and Consigned Assembly, Low Volume to Production, Cable and Harness Assembly, etc. for the manufacturing units in whole of USA.

PCB assembly